Our mission is to be the reliable partner for the ship owners and yards by helping them to increase revenue and decrease expenses.

In cruise ships revenue can be increased with interior revitalization projects, where the target is to increase passenger experience. This can be done by refreshing the passenger areas, creating trendy new restaurants, bars or modern photo studio. Furthermore, several new outdoor features like roller coasters, sport courts, waterslides etc. could be built. These works are usually done during the drydock, which is very unprofitable time for the ship owner. In addition to docking cost, ship cannot earn any turnover. That’s why drydock should be as efficient as possible and all the homework – design, planning, procurement, logistics – properly done.

At LTH Baas we are constantly trying to find new ways to improve the efficiency of each discipline and meanwhile still remain flexible. To proceed from good to excellent can be the longest way, but definitely the most interesting journey for us.

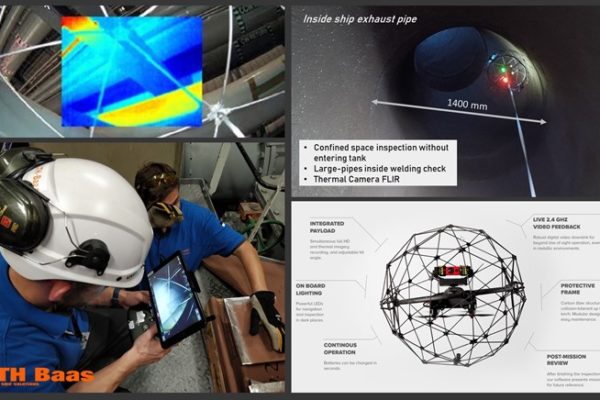

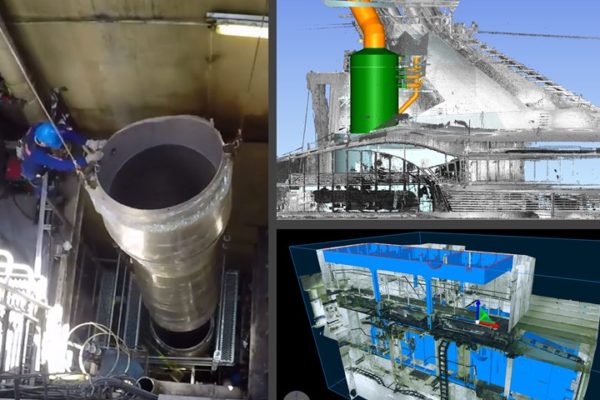

In retrofit projects the space is always very limited and thus, the accuracy of new build drawings is often not good enough. Few centimeters misalignments between large pipe spools and prefabricated structural parts, and unexpected clashes between existing structure can cause significant loss in installation time and quality.

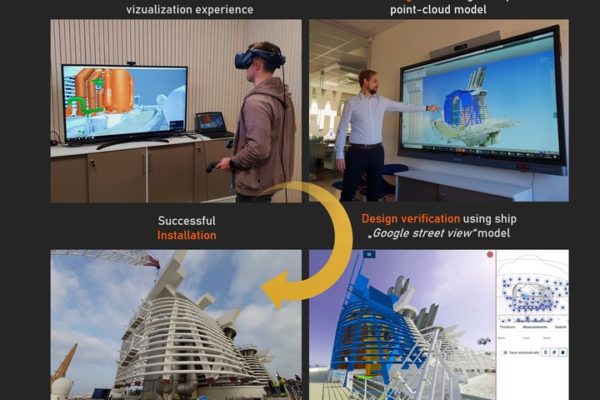

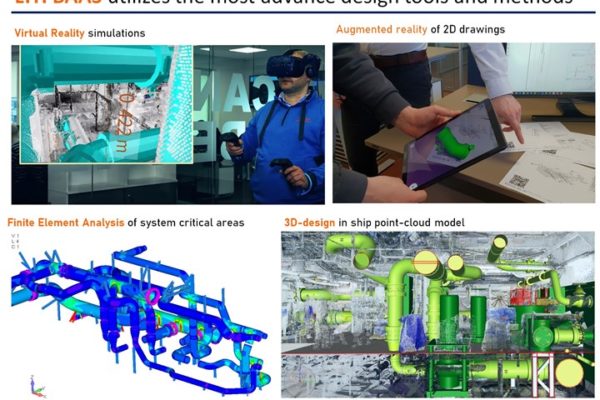

Our solution is laser scanning the ship spaces and creating point cloud model, where the accuracy is less than 1 mm, to make basic design and production drawings as accurately as possible. Virtual reality (VR) modeling is utilized to have true-life visualization for the ship owner, designer and it also helps supervisors in their “homework” in project preparation phase.

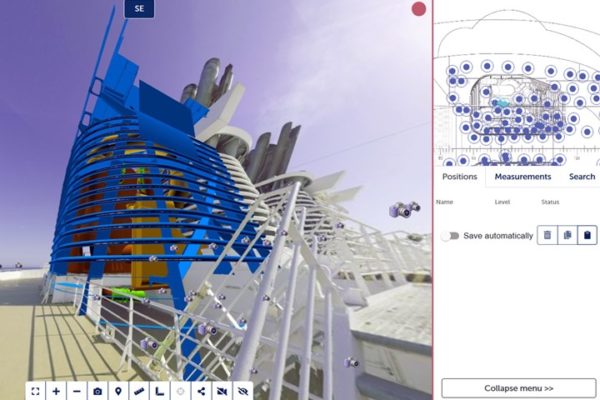

In VR-model they can check if there is enough space for welding and pipe works, prepare the lifting, transportation and get familiar with the project. VR is a very handy tool, but it requires specific equipment and software, therefore, Ayelix online portal is developed and utilized, which is like “Google Street view” of the vessel. This enables to walk around the project areas on board, take the measurements and check the design development remotely any time anywhere by all project parties. Such approach significantly decreases the number of site visits and design and verification can be done from distance.

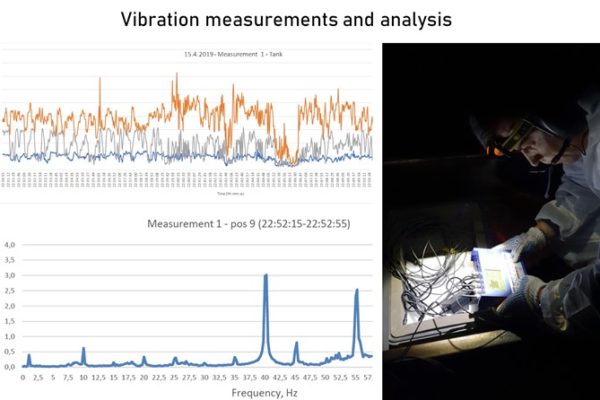

Considering structural reliability, LTH Baas leaves nothing to chance. Therefore, all critical and high responsibility structural members and piping systems are calculated against strength and vibration using finite element method. High level vibration can cause fatigue issues and create discomfort for crew and passengers.

LTH Baas is able to perform vibration measurements in new build and retrofit projects and by using advanced numerical calculation tools to determine the root cause of problems and provide the most cost and time effective solution for the ship owner.

Advanced design tools described above have been utilized in various LTH Baas retrofit projects: BWTS, scrubber system, SCR, shore power connection, structural build and repair works, etc.

No matter how large is the project or the ship owner’s problem, we treat it with high level standard.

Read more:

LTH-Baas introduced Smart Design of technical retrofit projects